Stamping Process includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages. Stamping Process includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produce the desired form on the sheet metal part, or could occur through a series of stages.

The stamping process we are conducting is on sheet metal only, but generally stamping process can also be carried out on other materials such as polystyrene.

In our factory, there are two types of press machine, progressive type (high speed) and hydraulic type.

The progressive type deals with hard materials for example silicon steel sheet.

The hydraulic types deals with usual type for example SPCC – SD.

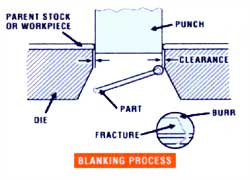

<< The next picture shows a two-dimensional illustration of a typical stamping process (progressive type). Note how the primary metal work piece remains and the punched part falls out as scrap as the punch enters the die. The scrap drops through the die and is normally collected for recycling.

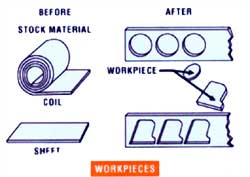

The following next picture shows the work pieces which could be created through the blanking process using either sheet or roll as the parent material.>>

The main factors to obtain a good quality of stamping process is as follows :

- Setting the metal mould properly into press machine.

- Setting clearance of punch(upper side) and die(lower side) of metal mould with high precision.

- Setting the burr tolerance according to specification.

The most common materials which our machines usually process are silicon steel, SPCC-SD

|